We place our relationship at the center of all our concerns, anticipate your needs and ensure that we respond quickly to all your requests. Flexible and available, we have chosen to master the entire production chain so that each service offered can also meet our expert expectations.

In order to meet our customers’ expectations and the requirements of the market, we follow an efficient process, integrated into a global offer.

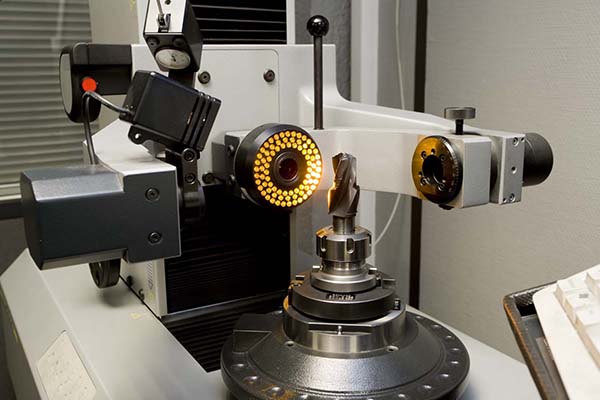

Needs analysis – Study and research of efficient solutions – 3D simulation of prototypes – Creation of tool plans

Tool analysis and contract review – Creation of production orders – Launch order – Grinding or manufacturing – Edge preparation – 5 poles – Sharpening to the standards of different manufacturers

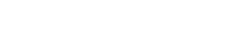

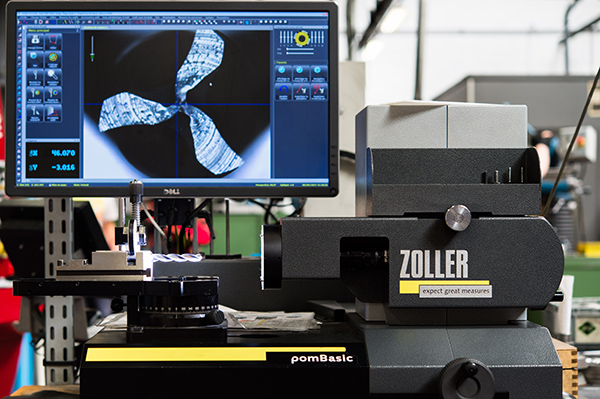

Dimensions and geometry check – Inspection report if required

Coating – barreling and cutting edges – Laser engraving of tools – Creation of feed channels

Monitoring and maintenance of tooling – Advice and optimization of machining strategies – Regular visits by a technical sales representative

AFLY is committed to offering its customers state-of-the-art production and control equipment.

To meet the needs of all its customers, AFLY has completed its offer with additional services.

Our national presence allows us to be as close as possible to our customers. The technical sales team regularly travels on site to ensure the collection and delivery of tools, but also to follow up on the delivered solutions and offer technical assistance if necessary.

We provide daily shuttles to two of our historical partners located within a 25-kilometer radius, to offer our customers a coating service for their tools in less than 72 hours.

We offer to engrave the machined parts according to the customer’s specifications, for example, to facilitate follow-up procedures. We will offer a Datamatrix laser engraving service that allows us to scan each part and to take note of its life sheet.

Sharpening with standards of the different manufacturers