Known for its expertise and reactivity, AFLY provides its customers with quality services in the field of cutting tool sharpening. At the cutting edge of technology, our fleet of machines dedicated to precision sharpening ensures a fast and complete handling of tools. Our control means are more and more efficient and guarantee a sharpening that can meet the standards of the different manufacturers.

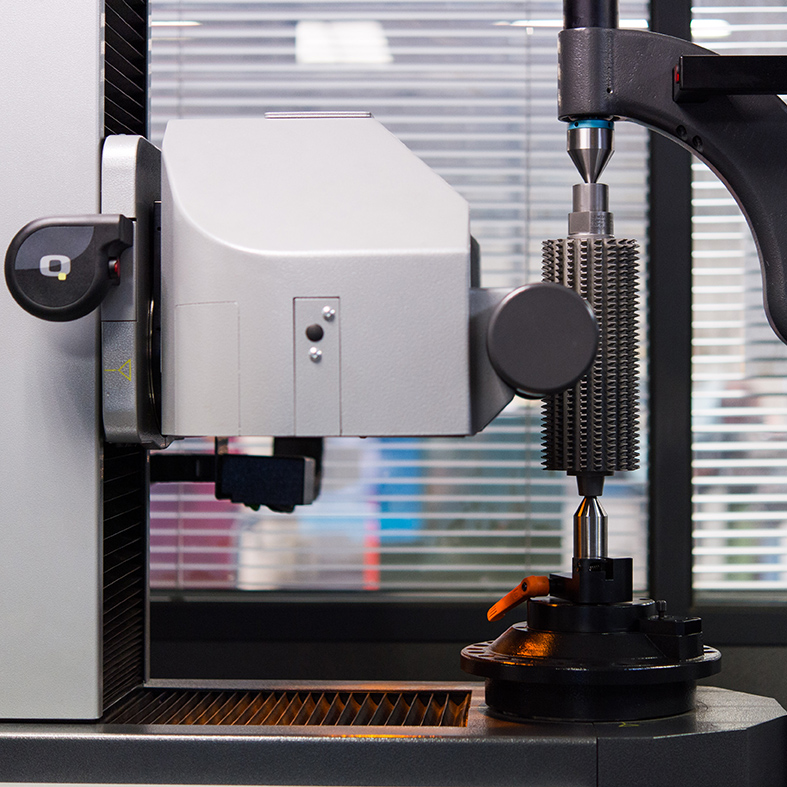

Certified by Gleason, leader in the manufacture of gear hobbing machines, AFLY ensures the maintenance of this type of tools. As part of this partnership, AFLY created in 2017 a complete workshop dedicated to the reconditioning of gear hobbing tools such as spur and helical gears. To further meet customer needs, we have also set up a stand-alone workshop dedicated to gear hobbing tools with an integrated stripping pole.

Sharpening with standards of the different manufacturers